Motivation: Carbon has a component in their 3D printers that requires the flow of air through it. The pressure and flow rate of this air is critical to ensuring print quality, at high speeds. Therefore, this component was flow tested. The motivation behind this project was to build a repeatable, automated flow testing setup.

I worked on the hardware, controls and software for this project during my internship at Carbon.

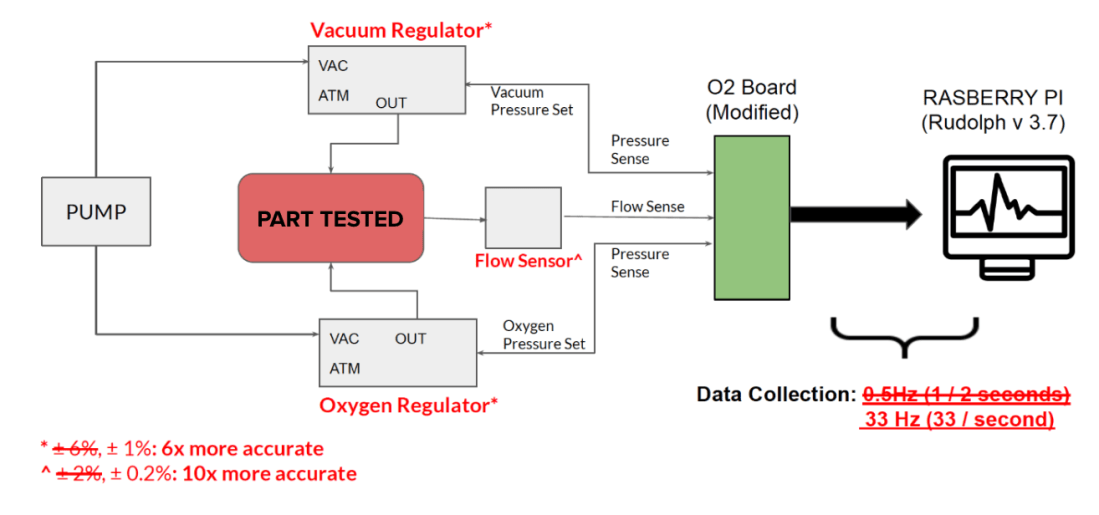

Hardware: I used a pump, pressure regulators and a flow sensor as a means to set/ control the pressure on either end of the component and measure the resulting flow rates. Additionally, ballasts were added before the flow sensor to reduce the noise- essentially acting as a low-pass filter.

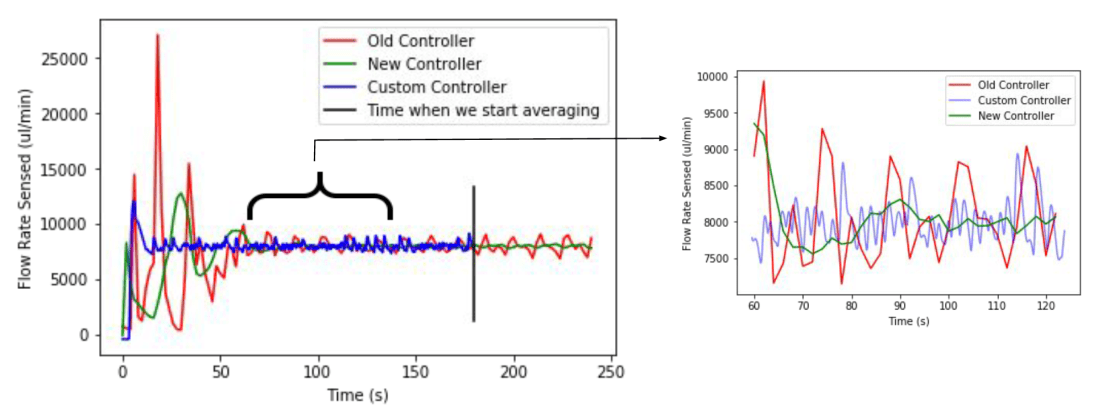

Controls: I implemented a closed loop control system using PID control to maintain a specific flow rate by adjusting the pressures. The results are summarized by the graph below. I build two solutions, referred to as ‘new controller’ and ‘custom controller’- one which optimizes for repeatability and the other which minimizes test time by settling quicker.

Software: I wrote code (Python) that allowed a user to add an arbitrary sensor/ component and read or write values to it. I also wrote code that integrated the Rasberry Pi (used for the test setup) with the overall software structure used in manufacturing.

Overall Impact:

The flow tester I build was 5x more repeatable and reduced cycle time by 3x. This was measured by running a custom calibration calibration piece on the original setup and the new setup I built. This allows for reliable testing at scale with tighter quality standards.

Additionally, the data collection rate with the Rasberry Pi was much higher than the original setup and the Rasberry Pi offers a lot of room for customization. Notably, this setup cost $2500, whereas off the shelf solutions that provide flow testing capabilities at the same accuracy cost around $20,000.