Motivation: Neuralink is building high-bandwidth, invasive brain-machine interfaces that need to be very precise in order to target specific neurons. In order to do this, the surgical instruments need to be manufactured at very high precision (± 1 micron). My challenge was to build the infrastructure to take the processes from being manual and time-consuming to being automatic, efficient and precise ones.

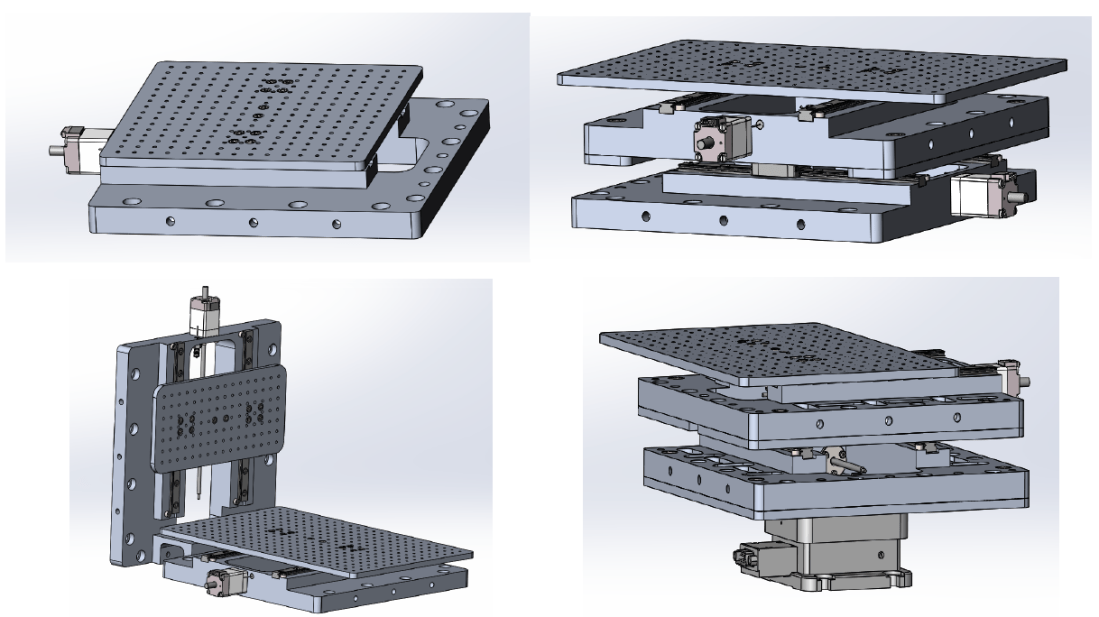

Automation Solution:

A lot of the processes that I automated required similar movement requirements. I developed custom linear-stages for Neuralink that had 5-micron resolution, 120mm travel and were stackable to extend the degrees of freedom as needed for the application. These stages are being used throughout the company for automation as well as for automated testing of components.

I primarily used these stages to automate the needle manufacturing process. This needle would be inserted into the brain and so needed to be manufactured very precisely. While I cannot display pictures of the needle and that setup as it is confidential information, I was responsible for the following:

- Built custom hardware that interfaced with the linear stages shown above to etch away the metal wire to get it to the required diameter

- Integrated in-line inspection for quality control and data collection

- Designing and implementing the electronics needed for the control system

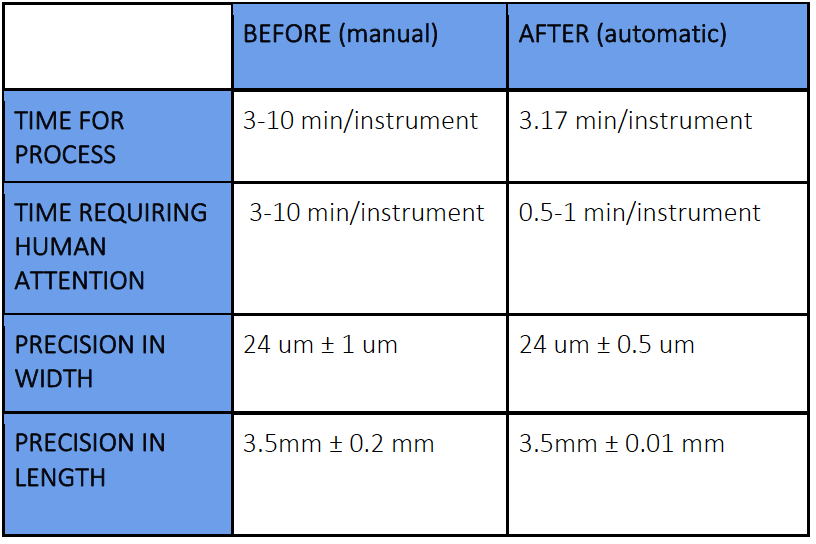

Results:

The table below shows the impact of the solution I designed- a 2x increase in precision of width and 6x-10x increased in efficiency (in terms of human effort).